Windsor's Flex-N-Gate partners to produce 'extreme fast charging' batteries for U.S. EV market

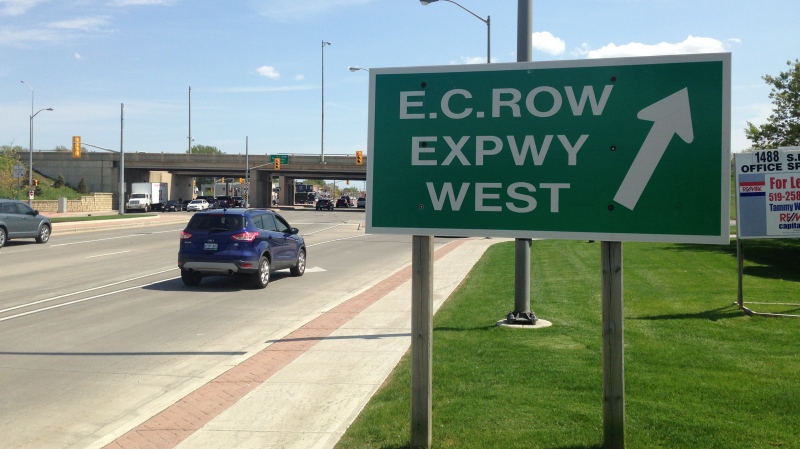

Battery electrode coating line at Flex-Ion in Windsor, Ont. (Source: StoreDot)

Battery electrode coating line at Flex-Ion in Windsor, Ont. (Source: StoreDot)

Windsor company Flex-N-Gate is joining a partnership to produce ‘extreme fast charging” (XFC) battery technology for electric vehicles in the U.S. market.

Flex-N-Gate is collaborating with StoreDot to sample and scale up the commercialization of StoreDot's game-changing extreme fast charging battery cells for electric vehicles.

Samples of StoreDot's 100in5 battery cells will be produced next year at Flex-N-Gate Group's "Flex-lon" lithium-ion cell pilot factory in Windsor, while working with local automotive OEMs to produce cells with specified performance and formats.

The 100in5 cells can deliver 100 miles of range in five minutes of charging.

"This is an exciting and significant agreement which further supports and enhances our path to OEM commercialization,” said StoreDot COO Amir Tirosh in a news release. “Working with Flex|N|Gate, a tier one manufacturer and global leader in mass-scale automotive component production, opens vast new opportunities for StoreDot in the North American market, including the ability to localize its cell production.

Tirosh said the 100in5 battery cells are already being tested by electric vehicle manufacturers.

“This strategic agreement gives us ability to scale up rapidly to mass production and flexibility to produce OEM li-ion battery cells at the scale and in the form factors required by this burgeoning industry,” said Tirosh. “Enabling owners to charge their cars safely in minutes is no longer an option, as range and charging anxiety remain the main barriers for mass EV adoption.”

Flex-N-Gate VP of Global Sales Guido Benvenuto said they are honored and excited to collaborate with StoreDot, an acknowledged innovation leader in the EV battery space.

“Producing extreme fast charging battery cells at giga-scale is a key competitive requirement in the electric vehicle industry. Applying our mass production manufacturing expertise to StoreDot's cutting-edge technologies will create an ideal framework to establish world-class cell manufacturing facilities,” said Benvenuto.

Early next year, cells will be produced at Flex-Ion's pilot plant in Windsor, where Benvenuto said they have established the capacity and flexibility to service the needs of the automotive industry.

“This will be a significant and rewarding development as the Americas transition to electrified mobility," he said.

CTVNews.ca Top Stories

W5 Investigates A 'ticking time bomb': Inside Syria's toughest prison holding accused high-ranking ISIS members

In the last of a three-part investigation, W5's Avery Haines was given rare access to a Syrian prison, where thousands of accused high-ranking ISIS members are being held.

'Mayday!': New details emerge after Boeing plane makes emergency landing at Mirabel airport

New details suggest that there were communication issues between the pilots of a charter flight and the control tower at Montreal's Mirabel airport when a Boeing 737 made an emergency landing on Wednesday.

BREAKING Supreme Court affirms constitutionality of B.C. law on opioid health costs recovery

Canada's top court has affirmed the constitutionality of a law that would allow British Columbia to pursue a class-action lawsuit against opioid providers on behalf of other provinces, the territories and the federal government.

Cucumbers sold in Ontario, other provinces recalled over possible salmonella contamination

A U.S. company is recalling cucumbers sold in Ontario and other Canadian provinces due to possible salmonella contamination.

Irregular sleep patterns may raise risk of heart attack and stroke, study suggests

Sleeping and waking up at different times is associated with an increased risk of heart attack and stroke, even for people who get the recommended amount of sleep, according to new research.

Real GDP per capita declines for 6th consecutive quarter, household savings rise

Statistics Canada says the economy grew at an annualized pace of one per cent during the third quarter, in line with economists' expectations.

Nick Cannon says he's seeking help for narcissistic personality disorder

Nick Cannon has spoken out about his recent diagnosis of narcissistic personality disorder, saying 'I need help.'

California man who went missing for 25 years found after sister sees his picture in the news

It’s a Thanksgiving miracle for one California family after a man who went missing in 1999 was found 25 years later when his sister saw a photo of him in an online article, authorities said.

As Australia bans social media for children, Quebec is paying close attention

As Australia moves to ban social media for children under 16, Quebec is debating whether to follow suit.