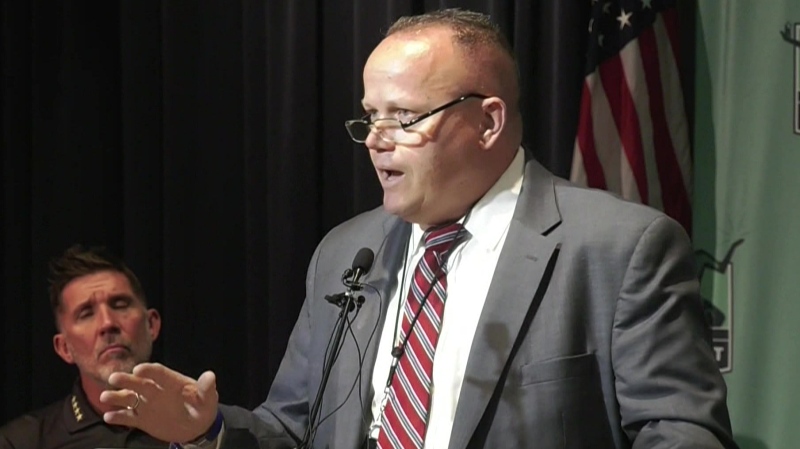

WINDSOR, ONT. -- Skilled trades workers are all back on the job, and the first shift of “team leaders” have returned to Windsor Assembly as planned, says Unifor Local 444 leader Dave Cassidy.

Video released by the automaker shows the factory floors have changed drastically since the industry came to a grinding halt back on March 17.

It shows lots of “lexan” glass, similar to plexiglass, draped from the ceiling down over the production line to allow workers to be physically distant from each other.

Inside Windsor Assembly, the minivans move along the conveyor and in the past, required workers to be sitting or standing very close to one another.

Not anymore.

“They’ve made some prototypes to go, if two people are working on the front of the vehicle, part of their job assignment will be to put that piece of lexin on there, to separate them,” Cassidy said.

According to Scott Garberding, global chief manufacturing officer for FCA North America, many of the new protocols came from the workers themselves.

“Other employees who have volunteered to come in and help with this. They have some really good ideas and I think it help make the workplace workable,” he said.

Mark Stewart, FCA’s Chief Operating Officer for North America says he would be comfortable sending his family to work in any of their factories. But admits, “we’ve got a few more things to do over the next week, to get the rest of areas closed that the teams are working on.”

Much of that work though, will begin at home for employees. FCA has sent home a package to all workers.

“The packages have a temperature strip in them, that temperature strip says whether or not you should be coming to work.” Cassidy said.

Workers must also answer four questions about their health in an online application before even leaving home for work.

Cassidy admits this is based on the honour system, and assumes members don’t lie if they aren’t feeling well.

But he says, every employee will be forced to walk through a trailer when they arrive on site, “where there will be an infrared camera that will solidify if the fact of whether they have a temp or not before they enter the facility.”

Workers will be wearing masks and safety glasses inside the factory at all times. The company is reminding workers the masks aren’t for their protection. But rather, to protect their co-workers.

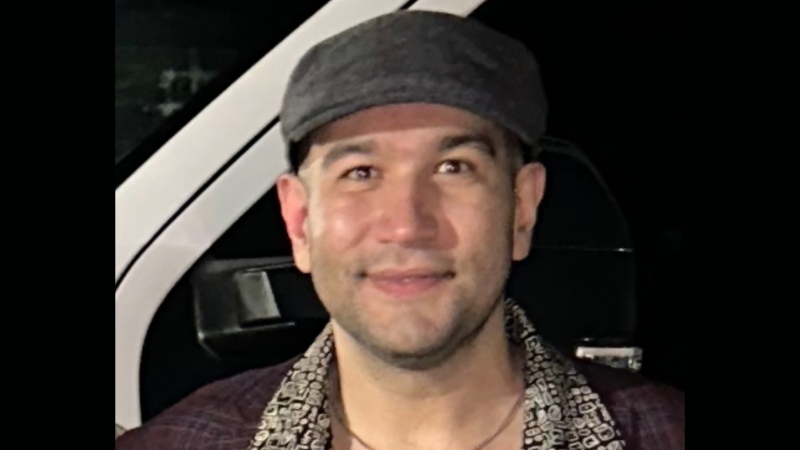

“If I came to work and I was sick without knowing it, if I were to cough or sneeze, it would be coughed or sneezed into the mask, thus protecting you,” Tom Vallone, division manager for environment health and safety, said.

Starting on Monday, just one shift will be working to begin production of minivans once again, Cassidy said.

One shift will be re-added every week thereafter, and the union is hoping all members will be back to work by the week of June 1.

He said even though the industry came to a “grinding halt” on March 17, there are parts in the system waiting at the factory to be installed in minivans.