Auto parts companies are partnering with the Ontario government to invest in technology and training with hopes of strengthening the auto industry and protecting jobs.

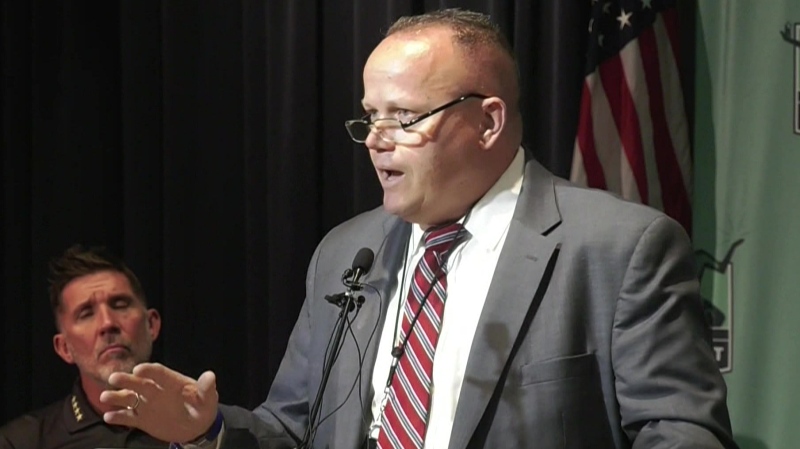

Minister of Economic Development, Job Creation and Trade Vic Fedeli, launched the new $10-million Ontario Automotive Modernization Program (O-AMP) at the annual meeting of the Canadian Association of Moldmakers in Windsor on Monday.

Fedeli says O-AMP is a key commitment of Driving Prosperity: The Future of Ontario's Automotive Sector, Ontario’s 10-year vision for how industry, the research and education sector, and all three levels of government, can work together to strengthen the auto sector's competitiveness.

“Our comprehensive, high-quality and innovative supply chain is essential to Ontario’s value proposition as a great place to build vehicles,” said Fedeli.

He says the launch of O-AMP further strengthens the close partnership with the industry to make Ontario open for business and open for jobs.

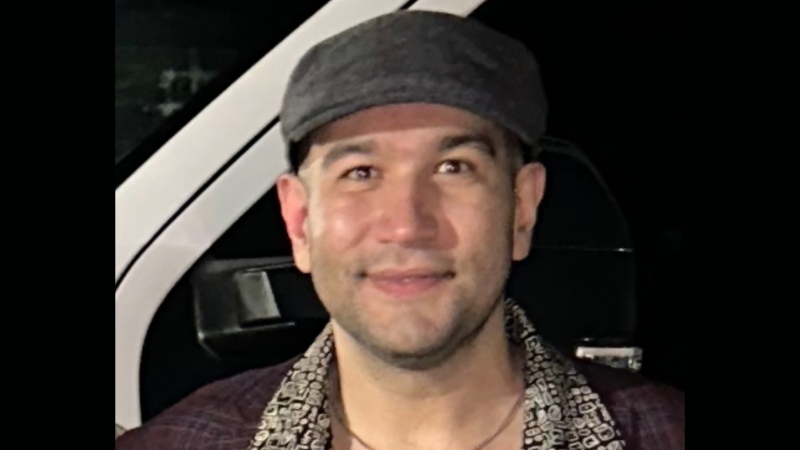

“Every day, CAMM’s member companies are striving to be at the leading edge of technology and innovation in the global moldmaking, service and supply sectors,” said Jonathon Azzopardi, chair of CAMM. “This support for technology investments and lean training boosts the long-term competitiveness Ontario’s automated manufacturing cluster.”

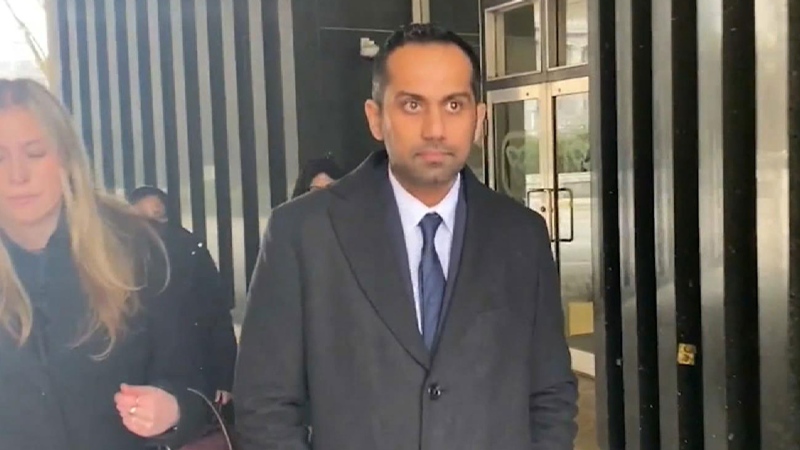

O-AMP funding will cover up to 50 per cent of eligible project costs up to $100,000 with recipient companies contributing the remainder through their own resources. Funding for O-AMP is $10 million over three years.

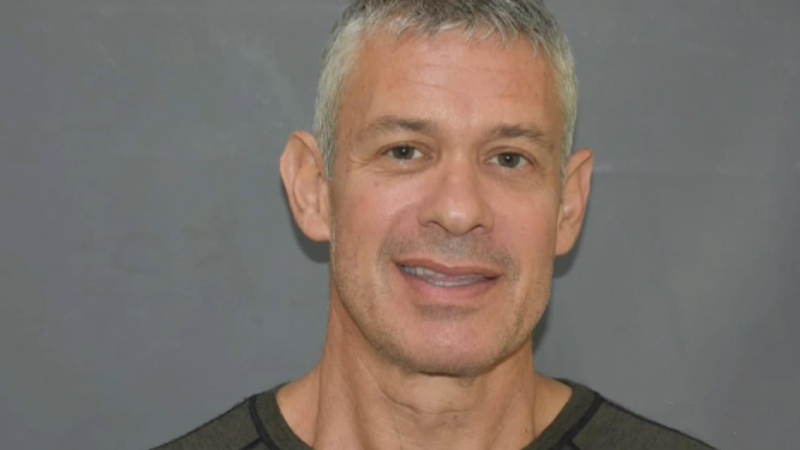

“With increasingly complex vehicle technologies, razor thin margins and global competition, every competitive advantage is a win for our industry and its workers,” said Flavio Volpe, president of the Automotive Parts Manufacturers' Association.

The new program invests with small- and medium-sized automotive parts suppliers in projects that fall under one or both of the following categories:

- Technology adoption ― includes advanced manufacturing hardware, software and/or training to improve processes and enhance competitiveness. For example, projects could include investments in production technology allowing firms to digitize their production tracking and logistical systems.

- Lean manufacturing ― includes projects that support training in lean manufacturing practices to minimize waste during the production process and optimize productivity.